Our QA managers about Food fraud and their expectations for the future

Food fraud is a much-discussed subject in the food industry at the moment. We asked our QA-managers’ opinions on food fraud and their expectations for the future.

Is food fraud now more prevalent than ever?

Our QA-managers’ opinions on the subject are divided. Nowadays one after the other food fraud scandal comes to light, but does this correspond with the actual number of food fraud cases? In any case, nowadays there’s more exposure to food fraud, according to our QA-managers: “Food fraud isn’t a new phenomenon. The milkman diluted the milk with water in the past. Above all, more cases of food fraud are known to us and the consumer nowadays”.

Both the producer, the media as well as the consumer are more aware of the food fraud phenomenon. Furthermore, nowadays research methods respond to detecting fraud more and more.

According to seventy percent of the interviewees, preventing food fraud begins with the producer: “The producer has primary responsibility, but we should work together to prevent food fraud. This includes the government, certifying institutions, the purchasing parties and the consumer.” Also, the majority of interviewees do not believe that a full assurance of food fraud is feasible in the food chain, although it does depend on the type of product: “You can make the production process as air tight as possible but there will always be cheaters.”

The length of the food chain determines the complexity of assuring. The internationalisation of the food industry doesn’t make detecting fraud any easier. Nevertheless, our QA-managers agree that it shouldn’t make a difference where the products come from. “The whole chain must be transparent and work properly.”

Unannounced audits

Unannounced audits are on the rise and will occur more often in future. Sixty percent of the QA-managers interviewed believe that this type of audit will uncover fraud cases early on: “A mutual trust must be created between food producers and customers. Unannounced audits by authorities, certifying institutions as well as customers can benefit mutual trust.”

Tools

New tools frequently arrive on the scene that respond to food fraud. These tools often cover a risk assessment of fraud within a company, such as risk analysis for raw materials and products. Our QA-managers find these tools to be effective aids. Yet more is needed to fight food fraud: “Risk analysis is a good first step, but the question is how one acts upon the results. The subsequent steps determine the effectiveness of the method.” An example of the next step is making use of product analyses, for example by means of a DNA test. These analyses are often expensive and therefore not always feasible.

There is a trust between food producers and customers in the ideal situation. Realisation of fraud is an important first step in preventing fraud according to our QA-managers.

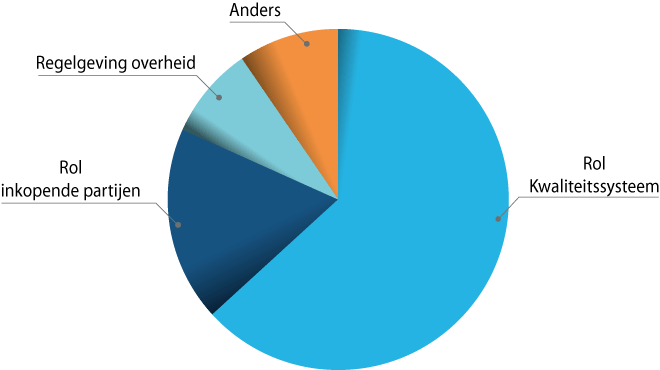

Larger role in the quality system

The detection of food fraud will be an important part of the quality system in future, according to our QA-managers, especially for companies that process raw materials that move through a chain with many links. Purchasing parties must also prepare for this. The conclusion for food producers is therefore clear: including fraud detection into the quality system will become imperative. The extra paperwork is readily accepted by the QA-managers. “Guaranteeing food safety remains our primary objective.”